Rotational Molding Leader

This method of Rotational Molding is likewise known as roto-moulding. This system can be a modern technology in line with the plastic-type material moulding. It is the best for producing content that are needed to get hollow. Within this technique of rotational moulding, there is no tension included. This system is really a casting approach. The rest of the tactics will not be, and therefore strain is applied in every those. It can be directed to create diverse item varies. The moulding can be carried out for any size and shape. There are no specific limits on its size along with its region.

Characteristics

It is a very helpful approach. As well as simply being useful, it is quite much useful as well. A few of the highlights of employing this moulding strategy are the following:

•It is definitely a convenient approach.

•It is really a process that is extremely a lot clear of any pressure.

•The plastic-type parts from the approach are very significantly lengthy-sustained.

•The plastic-type material elements are tough at the same time.

•This strategy is founded on a multi-move procedure.

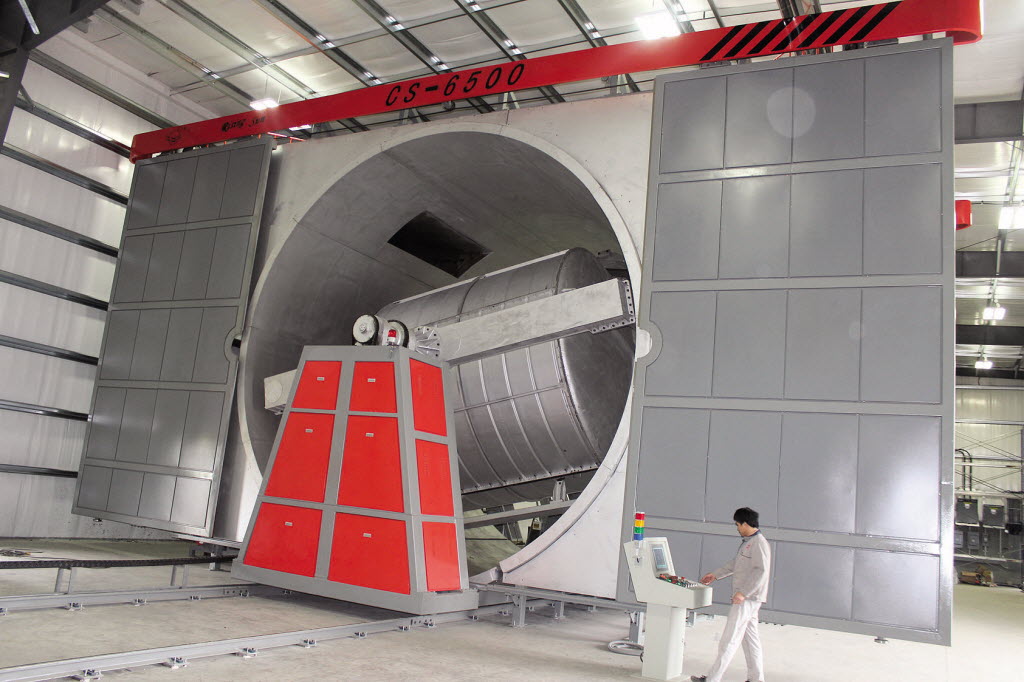

•This method employs rotation. They turn on two axes.

These are supplying four phases in their rotation moulding method. The techniques would be the resin that is made of plastic is filled in the mould. Then the next phase is the form is created to go to the heating system holding chamber. It really is positioned in an stove, and yes it starts turning at both its axes in a extremely low speed. The next stage entails air conditioning. The mould is now shifted to the chamber of air conditioning. This rotation still keeps on moving together with chilling employing air flow or drinking water. The last phase is the completed item is taken from the mould. The form then readies for the next pattern.