Understanding the Key Advantages of Rotomolding for Custom Manufacturing

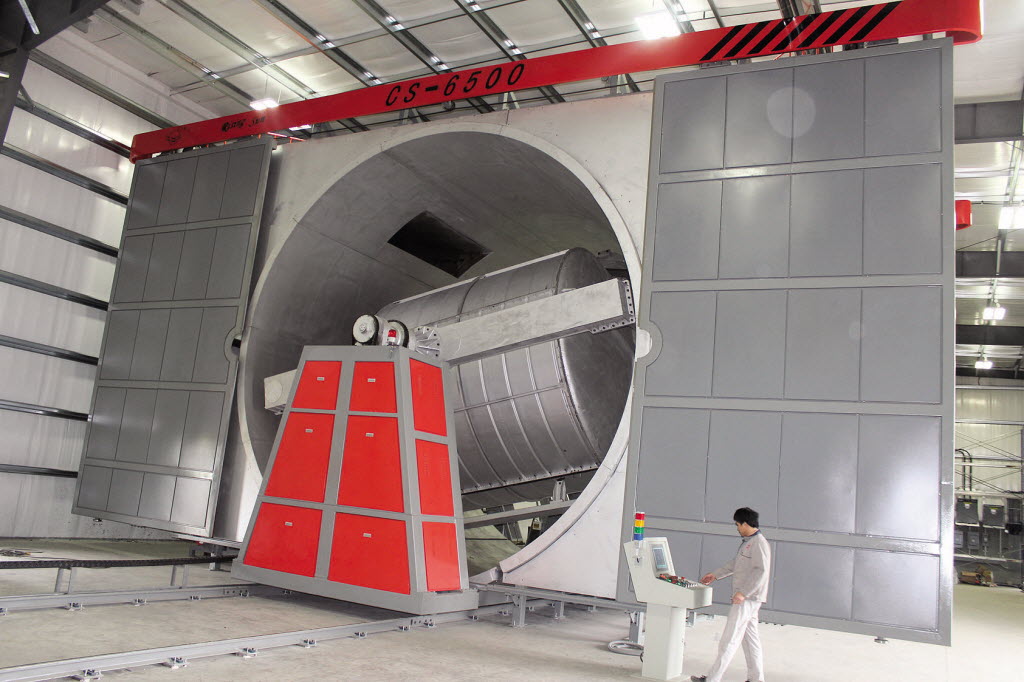

Rotational molding , or perhaps Rotomolding , is actually fast getting attention within the industry of personalized manufacturing due to the cost-efficiency, versatility, and skill to create intricate, durable parts. As businesses seek out impressive ways to supply high-quality merchandise together with small spend, rotomolding features several compelling advantages. 1. Layout Flexibility in addition to